OpenTherm

This feature is not included in precompiled binaries

When compiling your build add the following to user_config_override.h:

#ifndef USE_OPENTHERM

#define USE_OPENTHERM

#endif

Implementation of OpenTherm protocol

OpenTherm integration is based on OpenTherm protocol specification v2.2 and works with all OpenTherm compatible boilers.

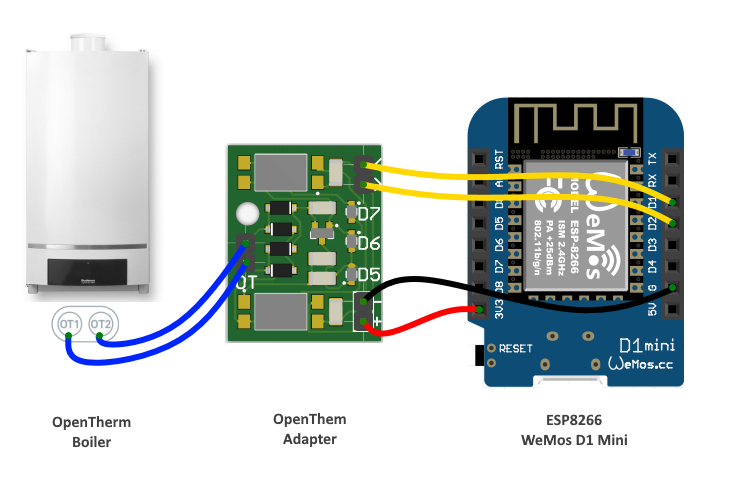

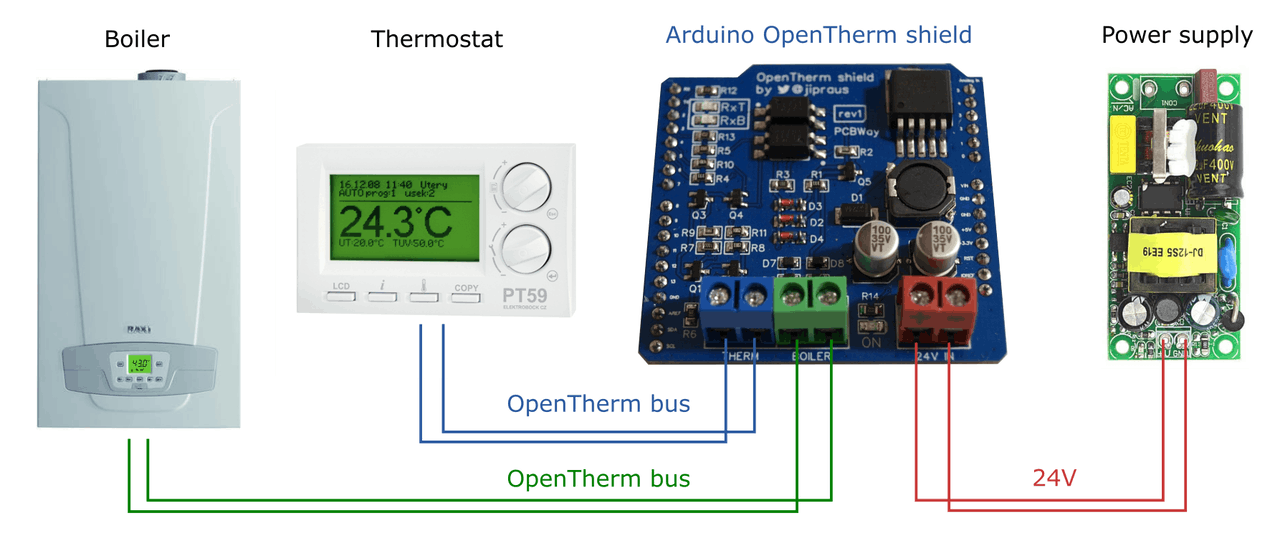

OpenTherm protocol requires a simple low voltage two-wire connection to the boiler, but voltage levels (7..15V) still much higher than ESP8266 levels, which requires OpenTherm Adapter.

Compatible OpenTherm Adapters~

- Ihor Melnyk OpenTherm Adapter

- OpenTherm Gateway Arduino shield

- OpenTherm master shield for Wemos/Lolin

All adapters have a fully isolated circuit from the boiler. However, please be aware that you can damage your boiler. You may also void your boiler warranty by installing this hardware. Please consult with your boiler manufacturer.

Note

For my home automation project, I used OpenTherm Gateway Arduino shield; however, this project uses OpenTherm library from Ihor Melnyk. I assume all adapters will work.

Please note, this integration does not work with the OTGW. You might want to take a look at the HA OpenTherm GW

Connecting to the Boiler~

Current integration acts as a master to the boiler.

Note

If OpenTherm master device is present, the boiler may disable its front panel controls. Users may not be able to set a boiler and hot water temperature through the boiler. Now it's the responsibility of the master device. This behavior might vary across different boilers.

You may disable this behavior by removing OpenTherm Slave Status command. However, the integration will not be able to read flame/heating/failure flags.

OpenTherm Gateway Arduino shield support a gateway mode. As of now, this mode is not supported by the integration.

As of now, gateway mode is not supported

Setting Up Tasmota~

Note

You need to define USE_OPENTHERM and rebuild Tasmota to enable OpenTherm integration.

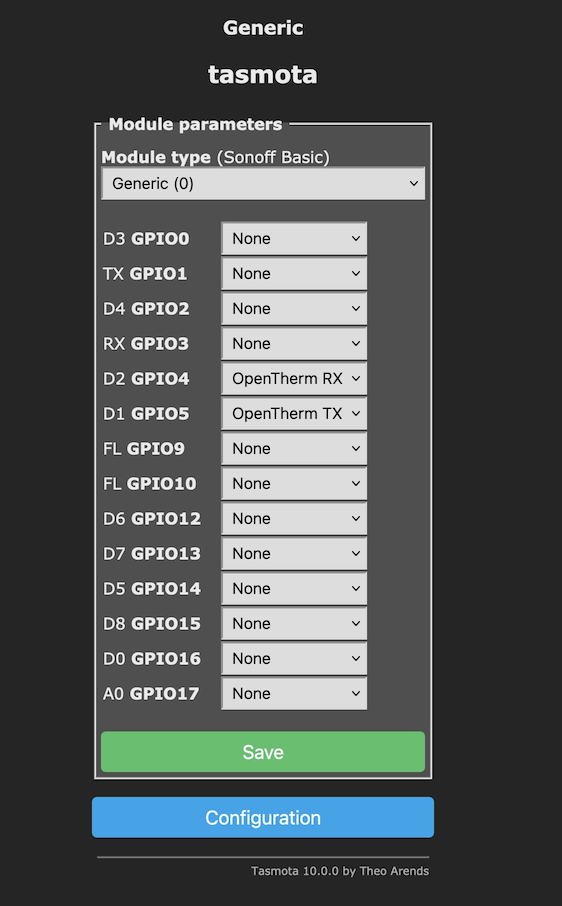

- Log into your Tasmota device

- Go to

Configuration->Configure Module - Select

Genericmodule type, save & restart - In the

Module parameterswindow, assignOpenTherm RXandOpenTherm TXto the corresponding pins - Save settings and restart

Note

The integration attaches ISR to the RX GPIO to avoid pooling. That GPIO should support interrupts. Please consider this while working on the schematics.

Troubleshooting~

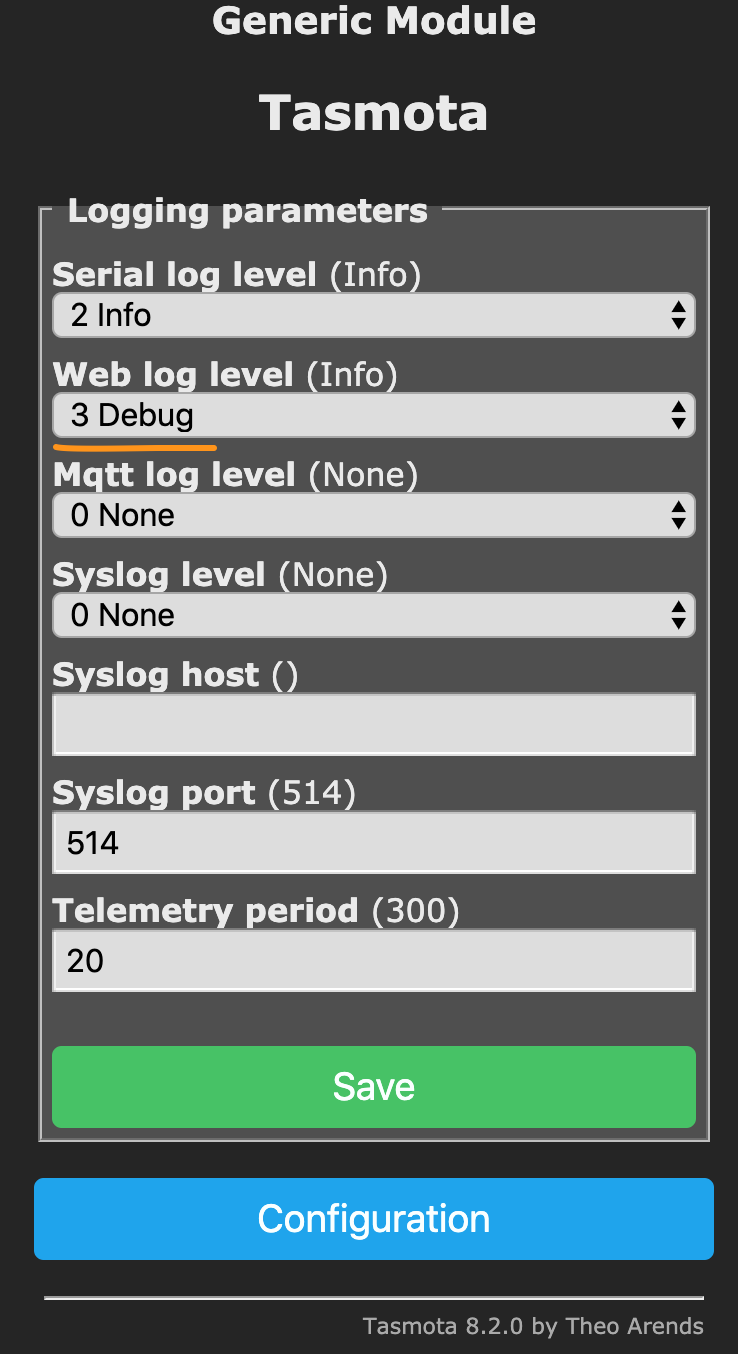

In order to troubleshoot you may need to enable Debug or More Debug logging level,

After restart you might see the following in the logs:

00:00:00 CFG: Loaded from flash at 3F7, Count 72

00:00:00 QPC: Flag 0E

00:00:00 CFG: CR 338/699

00:00:00 SRC: Restart

00:00:00 Project tasmota Tasmota Version 8.2.0(sensors)-STAGE

00:00:01 [OTH]: perform handshake

00:00:01 [OTH]: Processing response. Status=SUCCESS, Response=0x4003011B

00:00:01 [OTH]: getLastResponseStatus SUCCESS. Slave Cfg: 4003011B

00:00:01 [OTH]: Processing response. Status=SUCCESS, Response=0xC0000000

00:00:02 [OTH]: Setting Boiler Temp. Old: 0, New: 85

00:00:02 [OTH]: Processing response. Status=SUCCESS, Response=0xD0015500

00:00:02 [OTH]: Setting Hot Water Temp. Old: 0, New: 37

12:34:58 [OTH]: Processing response. Status=INVALID, Response=0x70730000

12:34:58 [OTH]: command OEMD is not supported by the boiler. Last status: INVALID

12:35:00 [OTH]: Processing response. Status=INVALID, Response=0xF01B0000

12:35:00 [OTH]: command TOUT is not supported by the boiler. Last status: INVALID

12:35:00 [OTH]: Processing response. Status=INVALID, Response=0x701C0000

12:35:00 [OTH]: command TRET is not supported by the boiler. Last status: INVALID

12:35:16 MQT: tele/boiler/SENSOR = {"Time":"2020-05-12T12:35:16","ANALOG":{"A0":7},"OPENTHERM":{"conn":"BUSY","settings":3,"SLAVE":{"FAULT":0,"CH":0,"DHW":0,"FL":0,"COOL":0,"CH2":0,"DIAG":0,"RAW":3221225472},"BTMP":{"FAULT":0,"REQ":85.0,"ACT": 85.0},"HWTMP":{"REQ":37.0,"ACT": 37.0},"ASFF":{"FC":0,"OFC":0},"FLM":0.0,"TB":31.0,"TDHW":30.0,"DHWS":37.0,"TMAX":0.0}}

In the example, perform handshake was successful, and the OpenTherm integration started to fetch various OpenTherm statuses.

Note

Your boiler may not respond to some of the OpenTherm commands. The integration made 3 attempts to execute the command. If the third attempt failed, the command marked as not supported and excluded from the rotation.

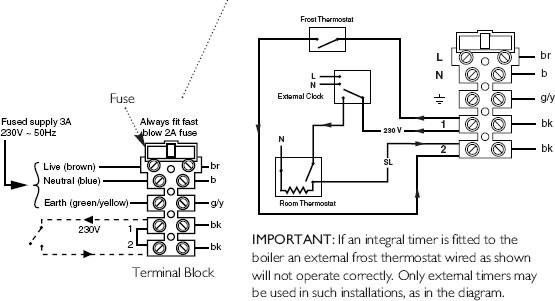

External Thermostat Wiring and Safety~

Central heating is the last thing you want to fail in your home. You might have significant damage to your property in case of the software bug or your custom hardware or wiring failure.

As a last resort measure, you probably want to use some sort of mechanical thermostat, which turns on your boiler if the temperature drops below the safe threshold.

In the worst-case scenario, your OpenTherm hardware stop communicating with the boiler. Proper boiler implementation will flag external panel error and take control back, following the external thermostat circuit state.

The second issue can be with your thermostat logic, especially if your logic is running on some external device. To address this, OpenTherm integration is using Diagnostics Indication to enable central heating. That way, if your external thermostat report freezing condition, OpenTherm integration activates heating. To enable this option, set the CHOD flag.

Note

Another use case for the CHOD flag might be an external hot water tank storage using central heating to heat the hot water in the tank.

Configuration~

OpenTherm integration supports the following commands.

ot_flagsGet/Set OpenTherm flagsot_tboilerGet/Set central heating temperatureot_twaterGet/Set domestic hot water temperatureot_save_setpointsSave central heating and domestic hot water temperaturesot_chActivate/Deactivate central heating

ot_flags command~

OpenTherm integration supports the following flags:

CHOD- Enable CH (central heating) on diagnostics flag. See External Thermostat sectionDHW- Enable Domestic Hot Water. If you have an on-demand gas heater, it won't start heating immediately, but enable heating when water is onCH- If set, activate central heating permanently, following theot_tboilersetpoint value. If disabled andCHODis set, it follows theDiagnosticsflag. Otherwise, heating is controlled by theot_chstatusCOOL- Enable cooling, if supported. Refer to your boiler manual.OTC- Enable external temperature compensation thermistor. Refer to your boiler manual.CH2- Enable auxiliary central heating. Refer to your boiler manual.

Note

During the first run, ot_flags is set to the CHOD,DHW. Hot water setpoint set to 36-degree Celsius and central heating temperature set to 85 degree celsius

To get OpenTherm flags, type ot_flags

13:49:48 CMD: ot_flags

13:49:48 MQT: stat/boiler/RESULT = CHOD,DHW

To set OpenTherm flags, type ot_flags DHW,CH,OTC

13:49:48 CMD: ot_flags DHW,CH,OTC

13:49:48 MQT: stat/boiler/RESULT = DHW,CH,OTC

ot_tboiler command~

ot_tboiler set boiler (CH) desired temperature. The actual command to the boiler will be issued if your new temperature difference bigger than the OPENTHERM_BOILER_SETPOINT_TOLERANCE value which is 1-degree Celsius as of today.

14:12:04 CMD: ot_tboiler

14:12:04 MQT: stat/boiler/RESULT = {"ot_tboiler":60.0}

14:12:55 CMD: ot_tboiler 85

14:12:55 MQT: stat/boiler/RESULT = {"ot_tboiler":85.0}

14:12:57 [OTH]: Setting Boiler Temp. Old: 60, New: 85

Note

Some boilers might write setpoint temperature into the Flash memory. Having PID controlled appliance may produce a lot of small fluctuations in the setpoint value, wearing out Boiler flash memory.

Warning

ot_tboiler do not write the value in the Tasmota settings, reducing Flash memory writes. To store it permanently, invoke ot_save_setpoints command after ot_tboiler command

ot_twater command~

ot_twater set domestic hot water temperature setpoint (DHW).

Warning

ot_twater do not write the value in the Tasmota settings. To store it permanently, invoke ot_save_setpoints command after ot_twater command.

14:13:55 CMD: ot_twater

14:13:55 MQT: stat/boiler/RESULT = {"ot_twater":38.0}

14:13:55 CMD: ot_twater 40

14:13:55 MQT: stat/boiler/RESULT = {"ot_twater":40.0}

ot_save_setpoints command~

ot_save_setpoints store boiler and domestic hot water setpoints into the flash memory of the Tasmota.

ot_ch command~

ot_ch enable or disable central heating (CH). The Boiler follows the ot_tboiler temperature setpoint.

14:14:57 CMD: ot_ch

14:14:57 MQT: stat/boiler/RESULT = {"ot_ch":0}

14:15:57 CMD: ot_ch 1

14:15:57 MQT: stat/boiler/RESULT = {"ot_ch":1}

Warning

ot_ch 0 won't turn the boiler off, if CHOD flag is set and external thermostat requires heat

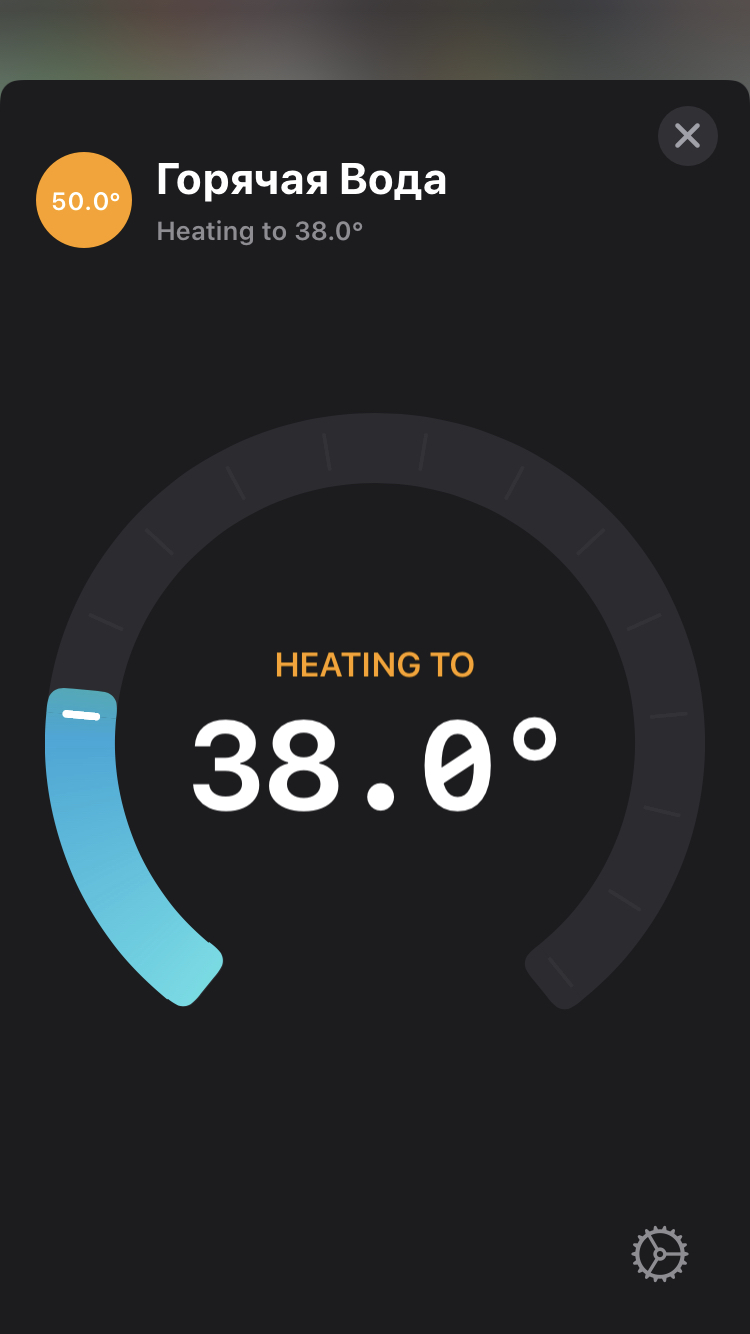

Setting Hot Water temperature~

One of the drawbacks, at least with my boiler, is that the boiler disables all the external knobs, so I can not set up the desired hot water temperature from the boiler itself. You might come up with the automation, setting hot water temperature by some schedule.

Another way is to use Home Assistant with the HomeKit integration. I created MQTT Hot Water Heater integration to the Home Assistant, so the Water Heater is exposed to the Home Kit. You should be able to install it through HACS

You can add the following configuration into the configuration.yaml of your Home Assistant set up.

water_heater:

platform: mqtt_water_heater

name: "Water Heater"

state_topic: "tele/boiler/SENSOR"

command_topic: "cmnd/boiler/OT_TWATER"

value_template: "{{ value_json.OPENTHERM.DHWS }}"

qos: 0

availability_topic: "tele/boiler/LWT"

payload_available: "Online"

payload_not_available: "Offline"

target_temperature: 38

heater_min_temperature: 35

heater_max_temperature: 50

Automation Examples~

This automation example turns on then Bathroom towel heater if someone is using hot water more than 5 minutes in the evening or more than 7 minutes in the evening. Bathroom towel heater has a coolant pump relay at 192.168.1.xx Also, it always turns on the heater on Clock#Timer3 event, working according to the schedule

It publishes state to the st/boiler/rr_dry for the Home Assistant bookkeeping. Also, it set boiler temperature to the %var3% value if external heating is required during the bathroom Dry mode.

Also, it syncs up the coolant pump state in case of the pump controller power outage.

# var1 - hot water ON time to enable bathroom Dry mode

# var2 - Bathroom Dry Mode boiler setpoint

# var3 - Normal Mode boiler setpoint

# var15 - a lock of the flame mode to avoid timer restart

# var16 - sync power4 state

# use VAR3 to set the actual boiler temperature setpoint

# If heat demand is on during RR Dry Mode, the temperature should be set back to the normal

Rule1

on system#boot do backlog TelePeriod 20; var1=540; var2=60; var3=85; var15 0; var16 0 endon

on tele-OPENTHERM#SLAVE#FL do WebSend [192.168.1.xx] POWER4 %var16%; endon

on Clock#Timer=1 do var1=300 endon

on Clock#Timer=2 do var1=420 endon

on Clock#Timer=3 do event dr=1 endon

on var3#state do ot_tboiler %value% endon

Rule2

on tele-OPENTHERM#SLAVE#DHW>%var15% do backlog RuleTimer1 %var1%; var15 1 endon

on tele-OPENTHERM#SLAVE#DHW=0 do backlog RuleTimer1 0; var15 0 endon

on Rules#Timer=2 do backlog ot_ch 0; ot_tboiler %var3%; var16 0; WebSend [192.168.1.xx] POWER4 OFF; publish st/boiler/rr_dry 0 endon

on Rules#Timer=1 do event dr=1 endon

on event#dr do backlog RuleTimer2 7200; ot_ch 1; ot_tboiler %var2%; var16 1; WebSend [192.168.1.xx] POWER4 ON; publish st/boiler/rr_dry 1 endon

Rule3

on tele-OPENTHERM#SLAVE#DIAG=1 do ot_tboiler %var3%; endon

on tele-OPENTHERM#SLAVE#DIAG=0 do ot_tboiler %var2%; endon